Stories for you

- WorldUSA TODAY

California valedictorian will no longer give graduation speech over 'alarming' discussion

The University of Southern California says Asna Tabassum will no longer speak at the ceremony after the discussion about her selection took on "an alarming tenor."

4K3 min read - SportsYahoo Sports

WNBA Draft winners and losers: As you may have guessed, the Fever did pretty well. The Liberty? Perhaps not

Here are five franchises who stood out, for better or for worse.

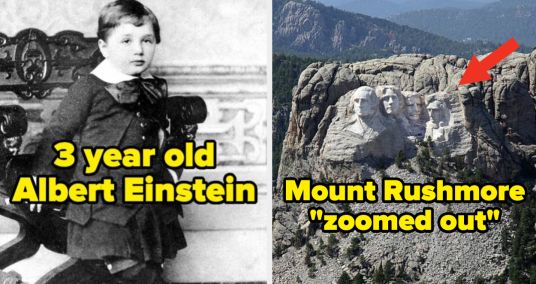

6784 min read - LifestyleBuzzFeed

15 Pictures That'll Have You Utterly Stumped For Several Minutes

Just some stuff that we witness on this little planet called Earth.

211 min read - WorldBBC

Russia to grow faster than all advanced economies says IMF

The IMF estimates Russia's economy will grow faster than the likes of the US, UK and Germany this year.

42 min read - SportsCNN

Chinese runner’s win invites suspicion after rivals appear to step aside

Chinese runner He Jie’s victory in Sunday in the Beijing Half Marathon is facing a probe after his win was called into question by Chinese internet users because a trio of African runners appeared to deliberately slow down to let him win.

8593 min read - LifestyleBuzzFeed

I'm Pretty Much The Dumbest Guy On Earth So These 21 Absolutely Incredible Pictures Absolutely Put My Brain In A Blender Immediately After I Saw Them

I am flabbergasted.

873 min read - LifestyleNY Post

I’m an ex-Mormon — here’s why members of my former church look alike

Alyssa Grenfell pointed out that Ryan Gosling, 43, was born Mormon, noting in her video caption that "he has Mormon face."

8783 min read - CelebritySheKnows

Suri Cruise Spotted on the Streets of NYC Days Before Her 18th Birthday & Yes, You’re That Old

I know, I know, I know. It’s probably not what you wanted to hear. (It’s not what I wanted to hear!) But somehow the little girl above — who was so famed in infancy — is about to turn 18 on April 18! Ahead of her milestone birthday, the notoriously private teen was spotted in …

192 min read - StyleINSIDER

The most daring looks celebrities wore to Coachella 2024

Many celebrities wore daring looks to Coachella 2024, from sheer dresses and miniskirts to bodysuits with cutouts.

2827 min read - NewsCNN

VideoBob Costas on what Johnnie Cochran told him privately after the OJ Simpson trial

CNN’s Bob Costas speaks with CNN’s Jake Tapper

604 - ScienceThe Weather Network

La Niña will make a comeback this summer as El Niño finally fades

The revised forecasts issued by scientists have been revealed, and the verdict is clear: La Niña will make a comeback

281 min read - LifestyleYahoo Life Shopping

Grab a viral anti-aging snail serum for $13 (nearly 50% off) — plus other incredible price cuts we found today

Shop massive spring savings on beloved brands, which include Dyson, Apple, Ninja and more.

01 min read - LifestyleINSIDER

I worked at Disney World for over 3 years. Here are answers to 8 questions guests are too embarrassed to ask.

As a former Disney World cast member who spent three years working in the parks, I've answered plenty of "embarrassing" questions from tourists.

1096 min read - LifestyleApartment Therapy

We Asked 3 Chefs to Name the Best Frozen Pizza, and They All Picked the Same One

Turns out, it’s a nostalgia thing.

323 min read - BusinessBenzinga

Bill Gates Is Raking In Over $1.26 Million Per Day In Dividend Income. Here Are The 5 Stocks Paying Him The Most

Bill Gates, the eighth richest person in the world, has a well-documented affinity for dividend income. This investment preference is clearly reflected in the staggering $463.2 million his portfolio is expected to pay him this year. Gates's investment strategy, rooted in picking companies with strong dividend yields, showcases his commitment to steady, long-term income streams. The Bill & Melinda Gates Foundation Trust’s most recent 13F filing reveals that a significant portion of this income is

44 min read - LifestyleTasting Table

A Bourbon Expert's Top Picks For Expensive-Tasting Bottles On A Budget

Bourbon can range from inexpensive to bank-breaking luxury, but just because you're looking to keep things cheap doesn't mean your bourbon can't taste fancy.

262 min read - OpinionThe Telegraph

America’s ‘God of War’ is now many decades old. The US Army can’t replace it

Forget the tank, the fighter jet and even the drone. Artillery is the most important weapon on the modern battlefield, just as it was 100, 200 or even 300 years ago. It was not for nothing that Stalin dubbed artillery the ‘God of War’.

1645 min read - USMen's Journal

Yellowstone Tourist Roars at Bison Before Getting Attacked

Being a respectful visitor who's mindful of flora and fauna is an essential part of visiting our national parks. But not everyone who gets out in nature knows how to leave everything as you found it. A video shared on Instagram by Tourons of Yellowstone showed what happened when a tourist ...

2842 min read - LifestyleSimply Recipes

The Only Way To Store Strawberries So They Last, According to Driscoll’s

The experts weigh on whether you should wash strawberries before storing and when it's time to toss them out.

33 min read - LifestyleUs Weekly

19 Perfect Bathing Suits for Athletic Body Types

If you have an athletic body type, there are a few key details to look for in bathing suits, and we have the best ones for you — details

373 min read